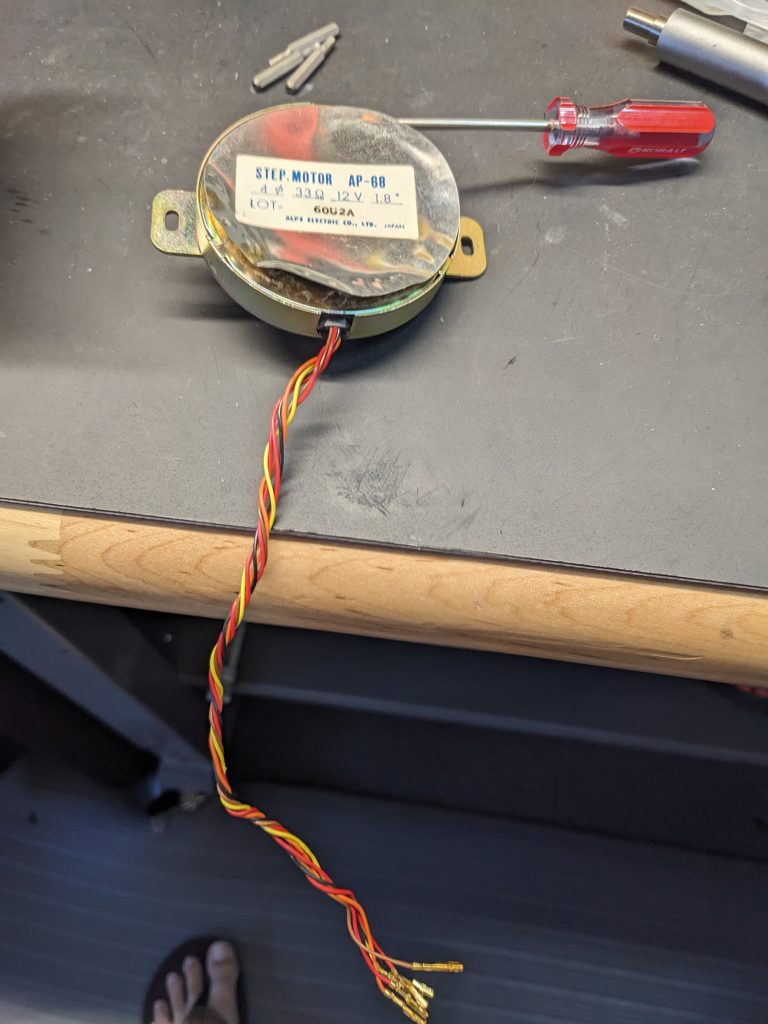

An Apple IIC floppy disk drive wasn’t working the other day. After lots of headscratching we find that the stepper motor is not functioning. After much circuit tracing, we checked continuity into the inductors of the stepper motor and found one of the four phases was failed, indicating a failed connection inside the stepper motor itself. Time to tear it open!

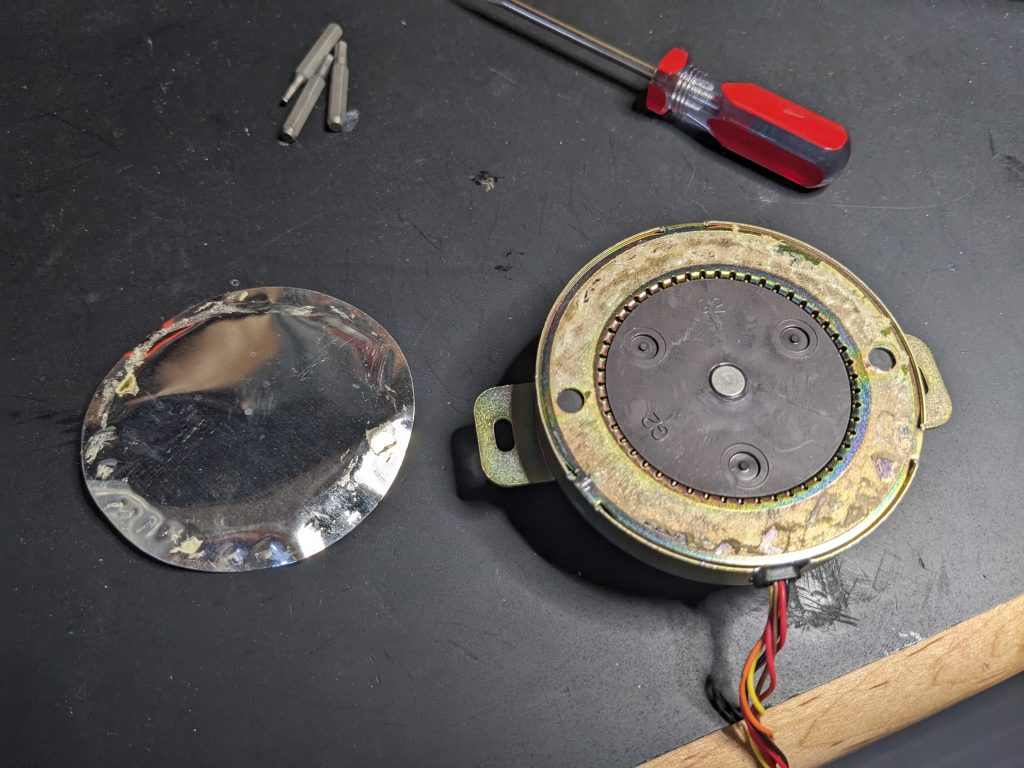

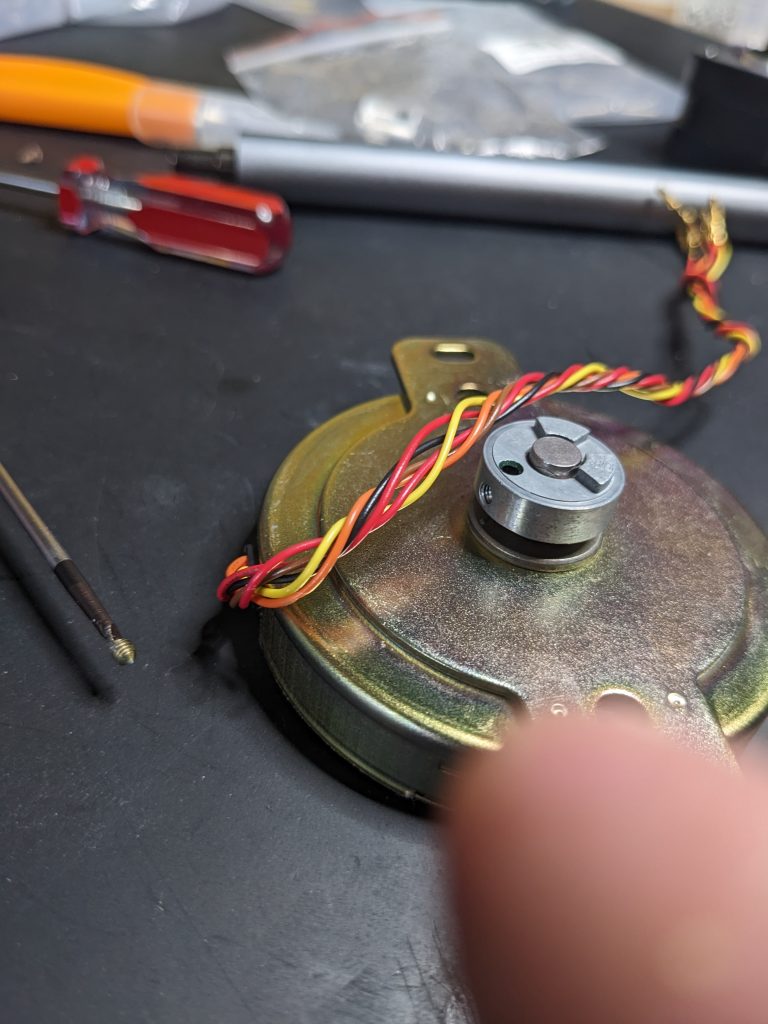

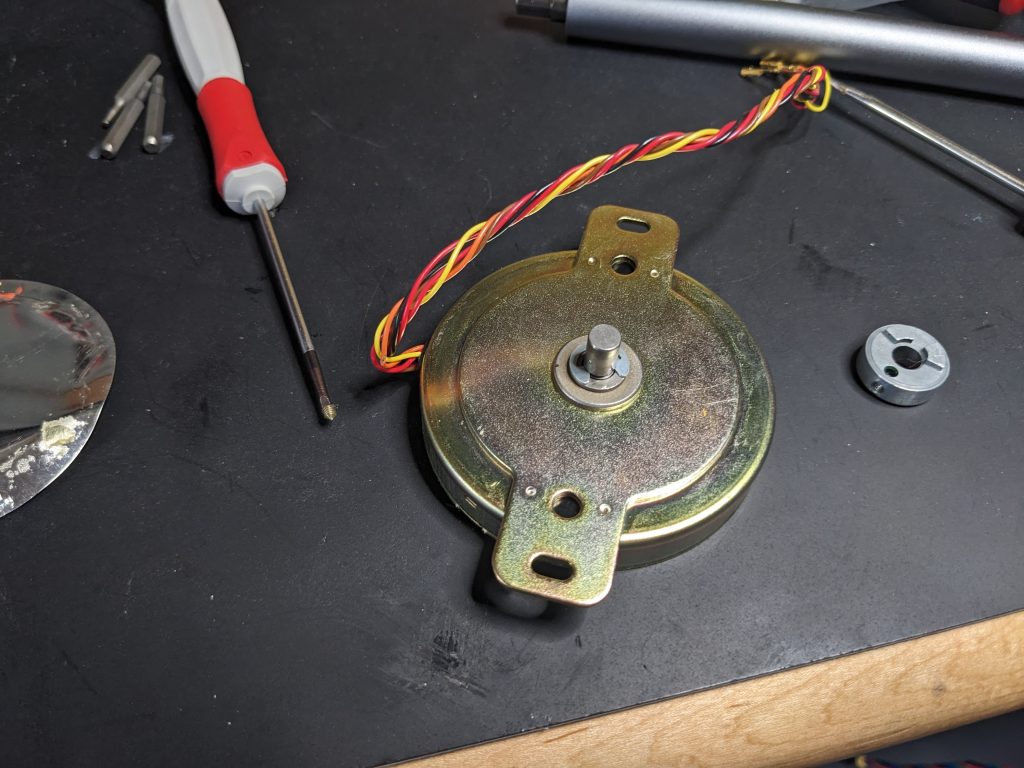

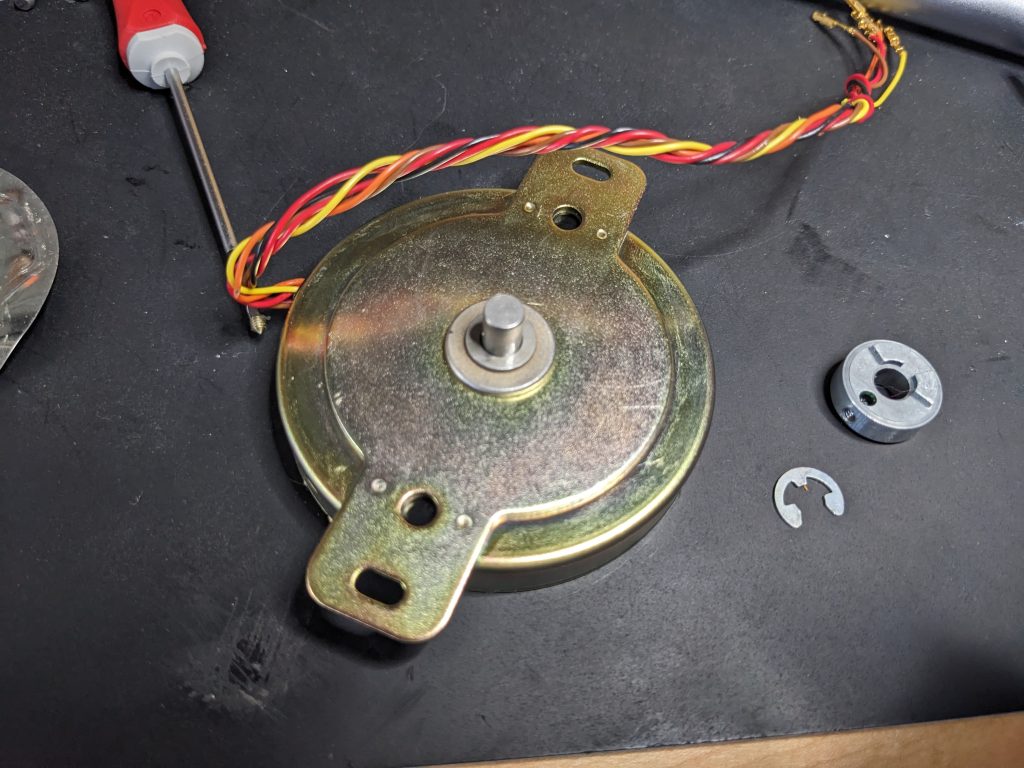

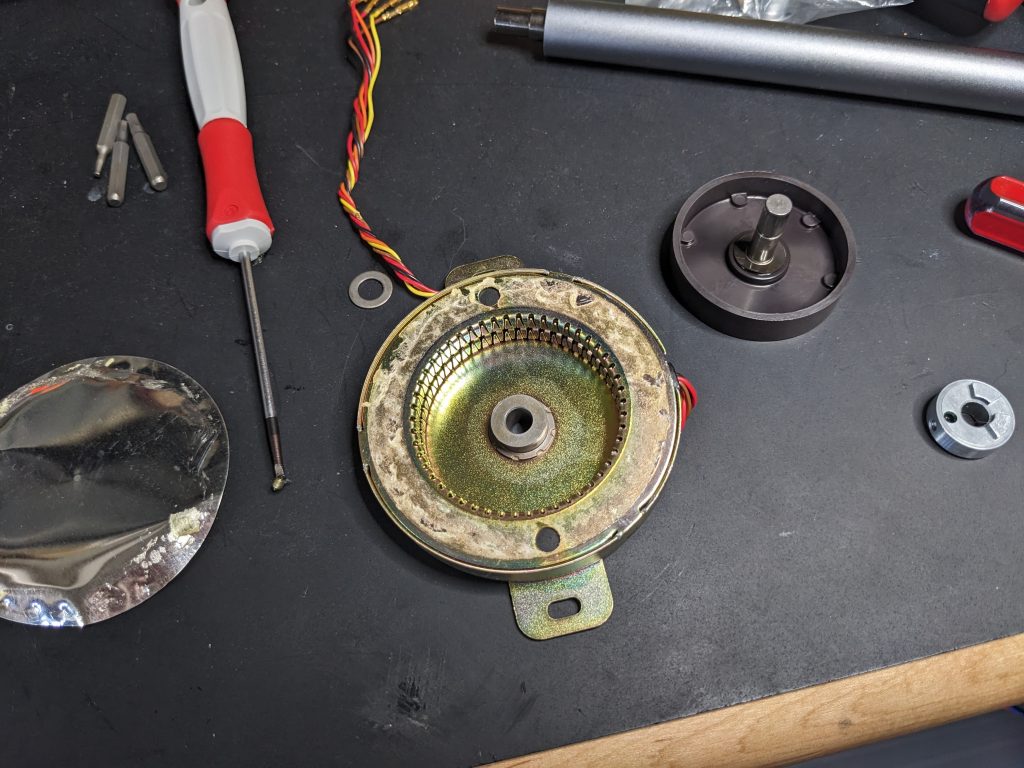

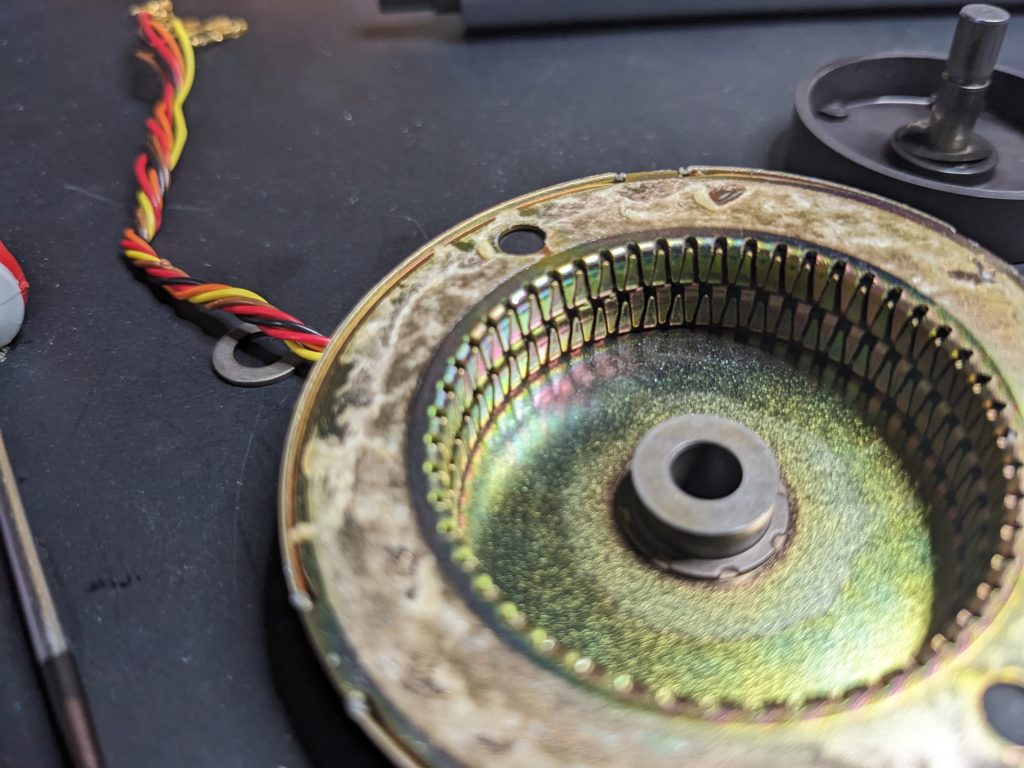

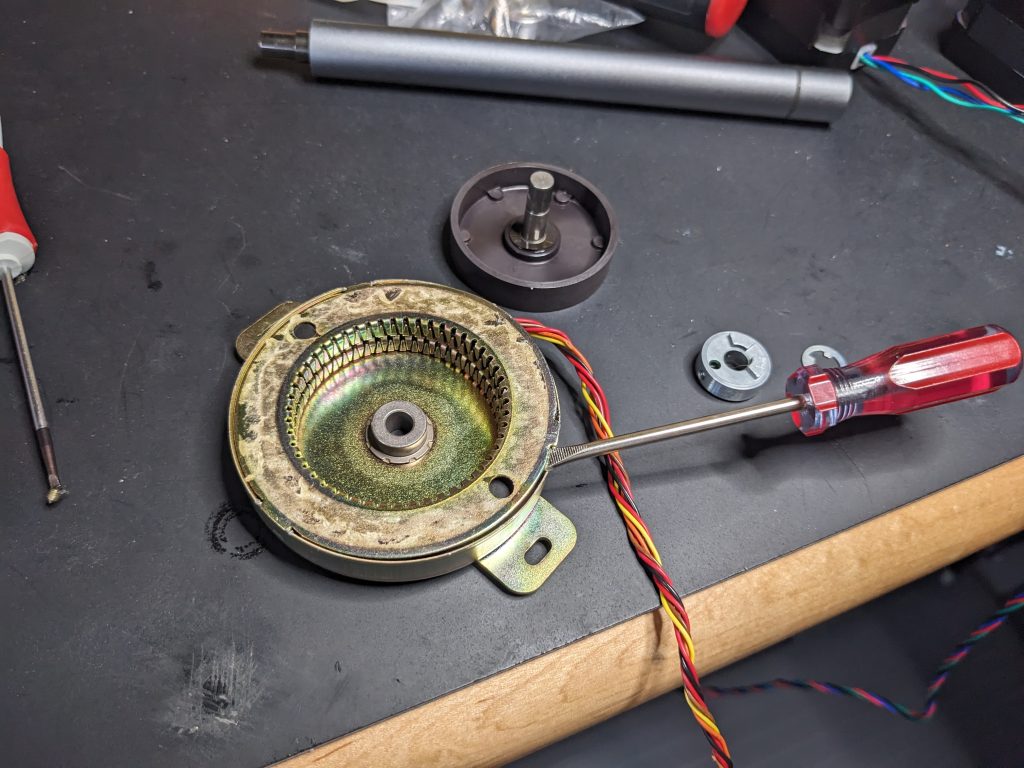

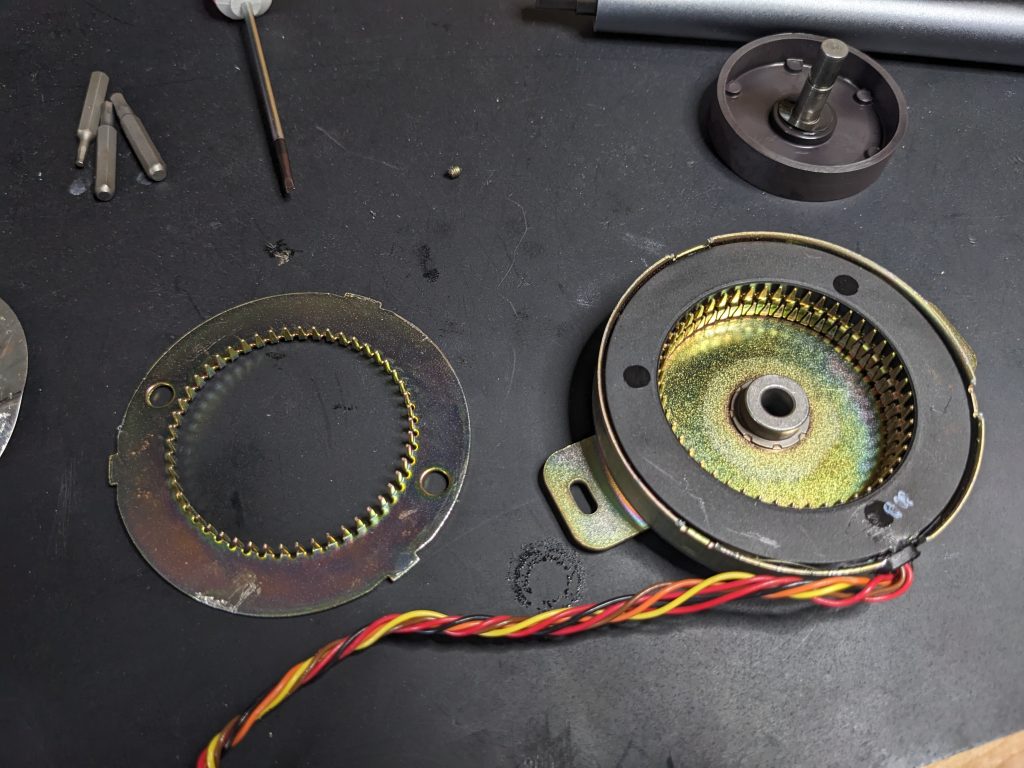

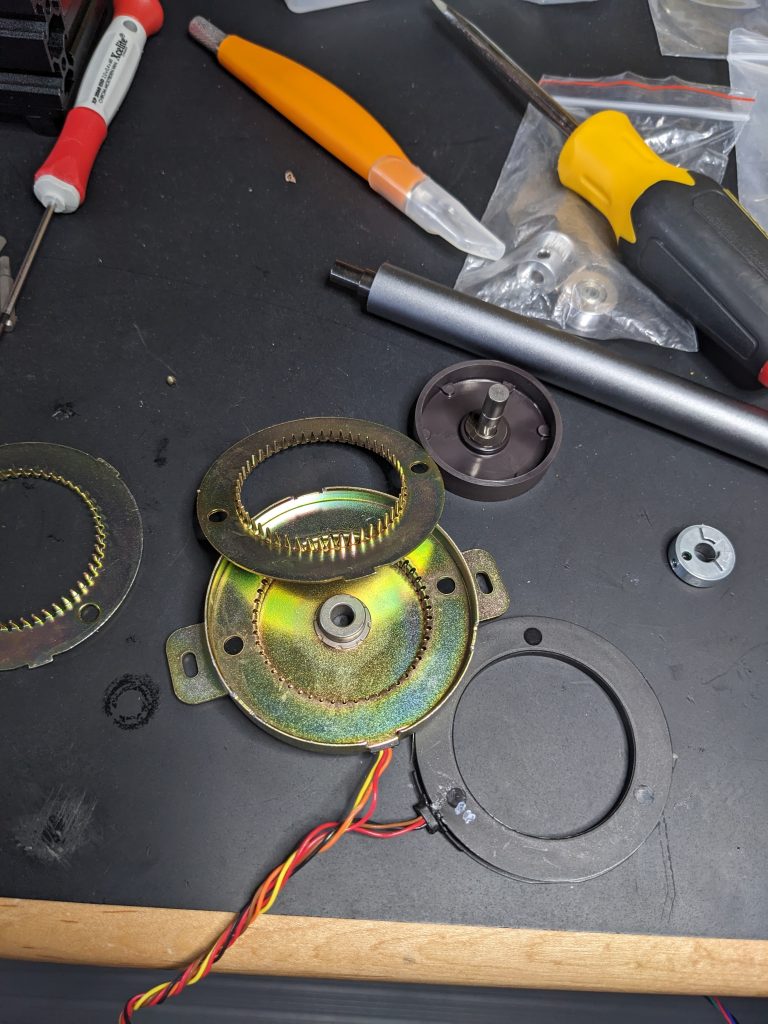

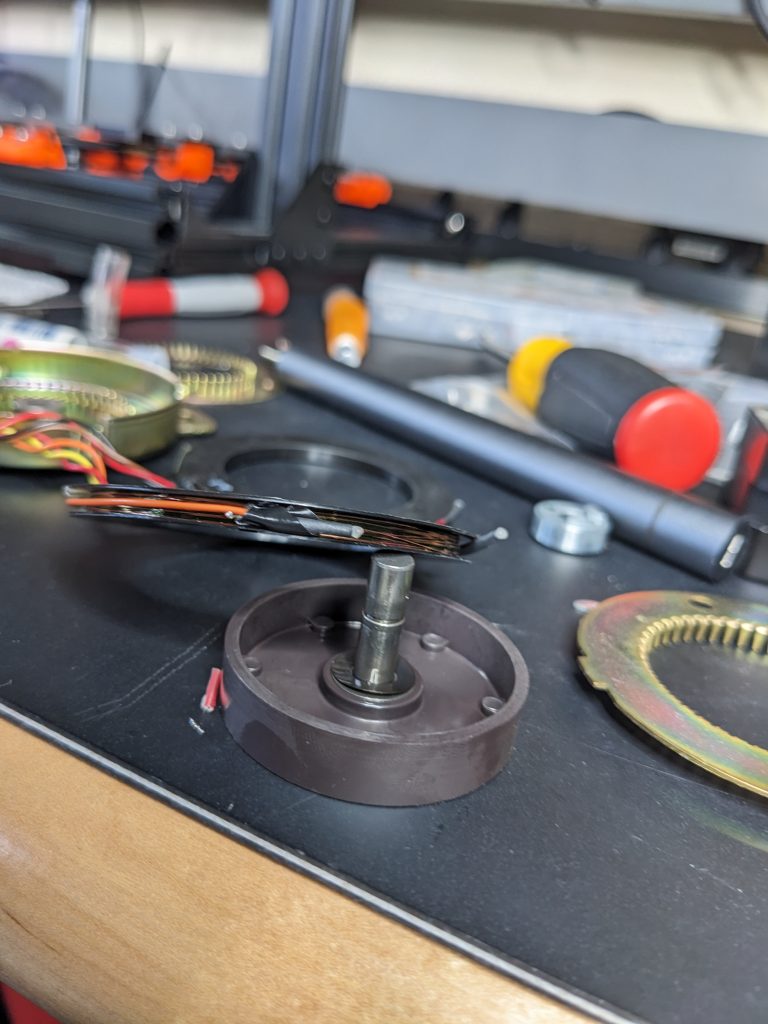

Many hours into the troubleshooting we frustratingly removed the AP68 from the drive and tore into it. So, here are a bunch of messy pictures of the insides. Towards the end of the slideshow you can see we diagnosed a bad connection from the orange wire to the stepper motor’s winding.

SLIDESHOW – CLICK ARROWS TO SEE MORE:

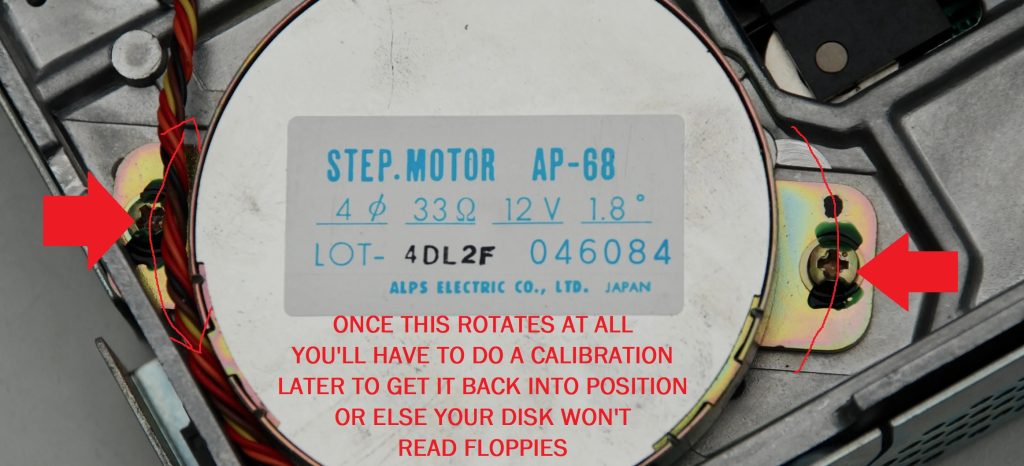

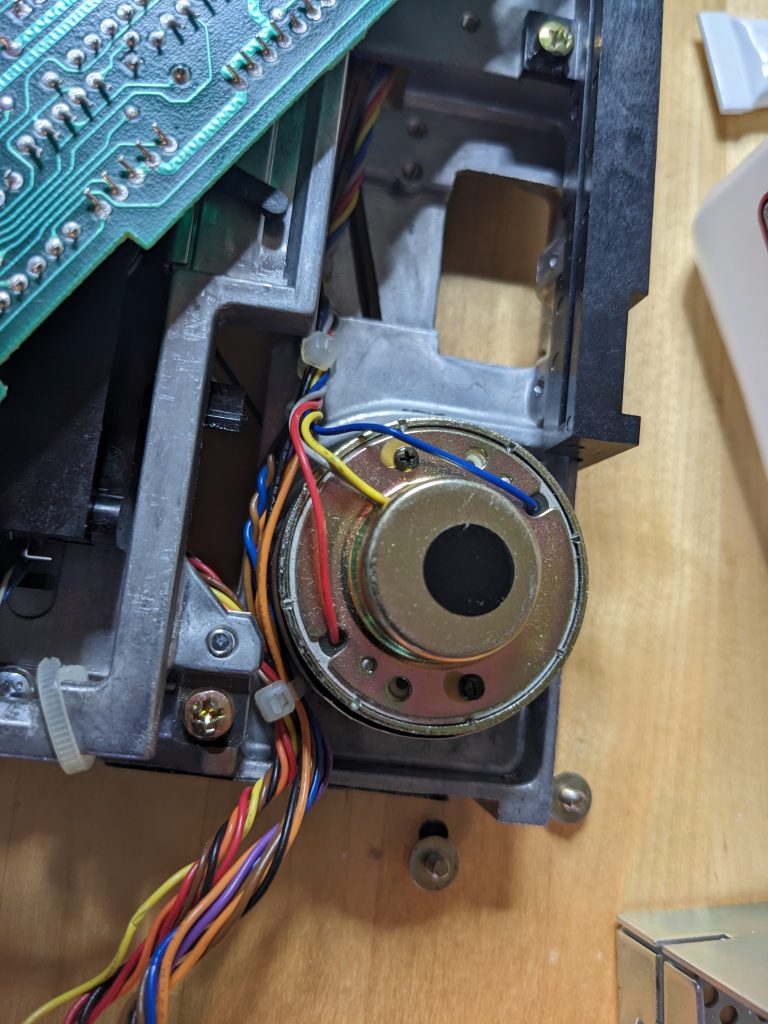

WARNING BEFORE YOU REMOVE YOUR AP68 STEPPER MOTOR FROM YOUR FLOPPY DRIVE: You can remove the AP68 from the Apple IIC floppy drive. However, you will have to do an alignment calibration when you re-install the AP68. It’s aligned by “rotating” the AP68’s shaft in relation to the floppy drive housing. It’s easy – just loosen the two screws on the AP68 and rotate the whole thing a tiny bit and then tighten the screws. The challenge here is being rotated the wrong way by a fraction of a millimeter can cause your floppies to stop reading. So, if realignment and calibration of the stepper motor does not sound fun to you, then don’t loosen the screws on your AP68 and don’t proceed. When it’s misaligned, it can usually still write new disks and read those disks, but it won’t be able to read any disks you previously wrote.

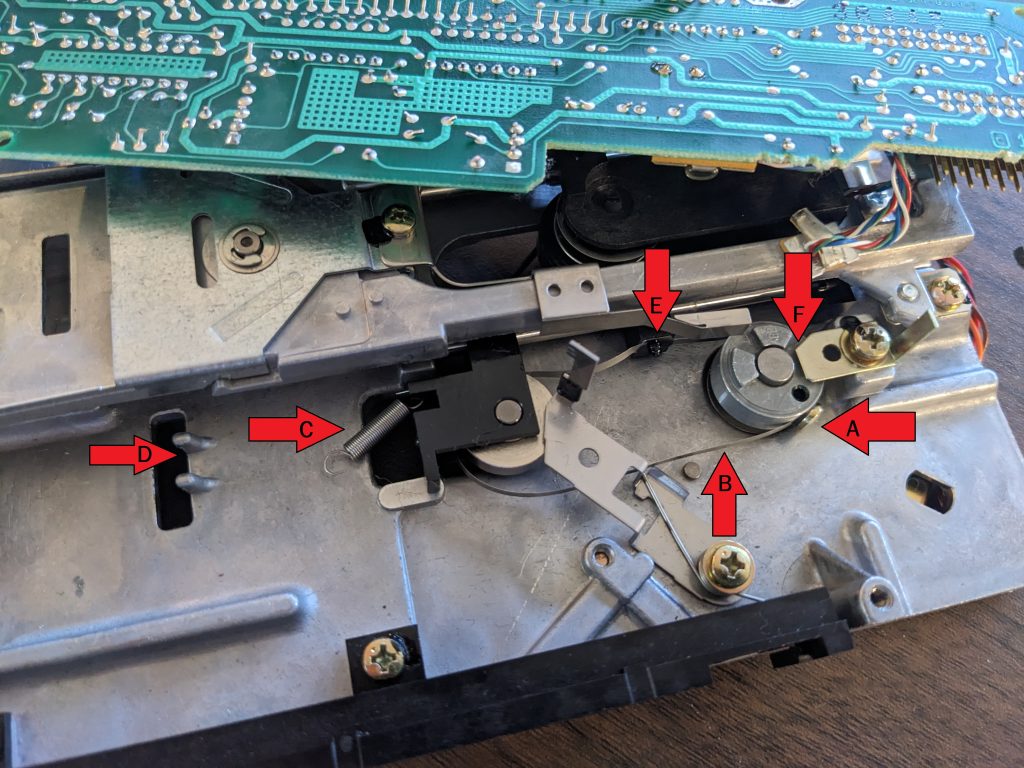

Ok, so in order to remove the AP68 you actually have to remove the securing screw from the top of the shaft (“A”) that attaches to the metal band (“B”) that in turn attaches to the read/write head carriage (“E”). Remember, the stepper motor’s function is to move your magnetic read/write head, which rides in the carriage, up and down the disk in small increments, so the read/write head can read each track on your disk. If you first detach the tensioning spring (“C”) from its anchor point(“D”) then the thing won’t explode on you when you loosen the screw at (“A”).

On a side note, check out point “F”. This is a physical stop point. When an Apple IIC boots, the disk controller has no idea what the current position of the stepper motor is. There’s no rotational position data. So the Apple II disk controller effectively “rams” this mechanical stop point for a few seconds, effectively zeroing out the read/write head and putting it at or near Track 0. This causes the stepper’s stopper to clack against the stopper tab (“F”). That banging sound is the familiar “clacking” sound you hear when you boot up an Apple computer.

WARNING: DO NOT LOOSEN THE BIGGER SCREW THAT HOLDS THE RECTANGULAR TAB AT “F” IN PLACE! You will lose the physical calibration of the mechanical stop to Track 0.

The easiest way to access this smaller securing screw is to actually remove the circuit board covering it. There’s a single screw to remove the circuit board, pull that circuit board out of the way, then remove the single securing screw (“A”) that attaches the metal band (“B”) to the shaft of the AP68.

Now, remove the two screws securing the AP68 to the housing and the AP68 should drop out of the hole. WARNING: Point of No return. Once you loosen these two AP68 housing screws (see below picture), your stepper will rotate slightly and become out of calibration and your floppies can’t read any more (until you recalibrate the rotational position of the stepper and rescure it).

You’ll have to untwist the AP68 control wires off from the other disk spinner motor wires, and you’ll have to use a tweezer to help remove the AP68 wires from the jumper plug. This doesn’t require any cutting or breaking of anything and you can easily reinstall the wires into the jumper plug later so long as you get the orientation correct (those little brass deals have four sides, you have to get the right side facing the right when when you re-insert them into the jumper plug later).

Congratulations, you have uninstalled your AP-68. Check out the other photos in the previous slideshow if you want to see it torn apart. Everything on the AP-68 can be dissassembled and reassembled safely.

Things we learned:

CAREFUL USING HEAT TO REMOVE THE ROUND METAL COVER. The round metal label is just horse-glued and can be removed with any spudger but it will bend your metal which will be hard to return to its pristine, beautiful flat shape. You could apply heat to loosen the glue.. HOWEVER please note that the application of too much heat could demagnetize the permanent magnets in your AP68 and cause it to not work any more! See this article here for more information on Curie temperature.

MARK THE POSITION OF THE SHAFT SET SCREW? You can remove the mechanical stopper off the stepper motor shaft by removing the tiny set screw. Doing this is advised, otherwise the other portions of the stepper will get “jammed” when trying to dissassemble everything. Remove the shaft first. We re-installed this tiny set screw near where it was removed. It left a little “dot” indentation from where it was originally installed so we just used that as the marker for reinstalling it. We have no idea if this effects your calibration or not later on. Just know that you should try to put everything back together the same way you removed it.

AP68 ALIGNMENT PROCEDURE: When your AP-68 has been physically rotated from its original position, it can usually still write new disks and read those disks, but it won’t be able to read any disks you previously wrote. Thanks much to the guys in the Atari Age forums for a crude method for finding the coarse rotational alignment for your AP68 when you re-install it.

- Download a DOS 3.3 image, I used this one: https://mirrors.apple2.org.za/ftp.apple.asimov.net/images/masters/Apple%20DOS%203.3%20January%201983.dsk

- Bootstrap into your computer with your miscalibrated Apple IIC drive using ADTPro and a ADTPro serial cable (instructions not provided here)

- Send the DOS 3.3 disk image to your disk. If you can’t even write to your disk at this point, you’ll have to guess-and-check the rotation of your AP68 until it will at least start writing disks.

- Reboot, you should get a DOS 3.3 command prompt.

- Now, remove your DOS 3.3 disk you just made (that was made with your mis-aligned AP68), and insert a known good disk.

- Type these three lines:

10 ONERR GOTO 20

20 PRINT CHR$(4)”CATALOG,S6,D1″

30 GOTO 20

RUN

This above script will attempt to read the catalog information off of your known good floppy disk. Replace “S6” (Slot 6) and “D1” (Drive 1) as necessary (for example, when trying to calibrate an external disk drive). Your drive will be good and loud at this point. At this point, you can loosen the two screws on the AP68 and rotate it (tiny amounts, fractions of a millimeter, good hand-eye coordination needed) until the DOS 3.3 program successfully reads out the catalog information.

COMMODORE 1541 RELATION: It turns out the Commodore 1541 drives are ALPS drives and are extremely similar to the Apple IIC internal ALPS drive, including the use of the AP68 stepper motor. So if you have a completely bad/corroded stepper motor, you may be able to get a spare either from a broken Apple drive or a broken Commodore drive of certain models.

USEFUL LINKS: Additional useful links regarding calibration and alignment:

- https://www.applefritter.com/content/apple-iic-disk-replaced-bad-stepper-now-calibration

- https://forums.atariage.com/topic/327327-calibration-and-alignment-of-duodisk/

- APTEST calibration software (requires using CiderPress to convert to a usable .DSK or .DO image) https://mirrors.apple2.org.za/ground.icaen.uiowa.edu/Collections/Buggie/

- Old magazine article on the use of M68SP-4 (similar to AP68) four-phase stepper motors https://worldradiohistory.com/Archive-Radio-Electronics/90s/1999/RE-1999-11.pdf

Hi, this is a comment.

To get started with moderating, editing, and deleting comments, please visit the Comments screen in the dashboard.

Commenter avatars come from Gravatar.